When exploring printing techniques, you may come across terms like “embossed printing” and “debossed printing.” Both techniques add a tactile dimension to printed materials, enhancing their visual appeal and texture. But what exactly are these methods, and how do they differ? In this article, we will delve into the nuances of embossed vs. debossed printing, examining what makes each technique unique, their applications, & how they can impact the overall design of your printed materials. Let’s break down what embossed printing is, what debossed means, and how these techniques compare.

What is Embossed Printing?

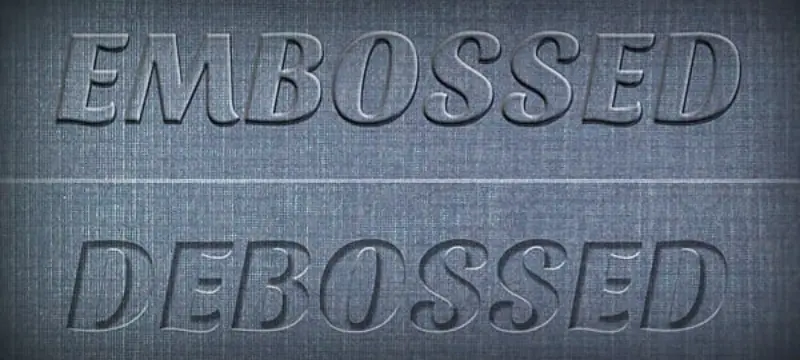

Embossed printing creates a raised design or text on a surface, resulting in a three-dimensional effect. This process is achieved by using a die to press the design into the paper or other material, causing the surface to rise. The raised elements can be seen and felt, adding depth & texture to the printed piece. This technique is often used for business cards, stationery, packaging, and other high-end printed materials where a touch of sophistication is desired.

Benefits of Embossed Printing

- Enhanced Visual Appeal: The raised design draws attention & adds a tactile element that engages the senses.

- Luxury and Elegance: Embossing is frequently used in premium print jobs to convey a sense of quality and refinement.

- Durability: The embossed elements can be more resistant to wear and tear compared to flat printed surfaces.

Common Uses of Embossed Printing

- Business Cards: To make a memorable impression with a tactile feel.

- Stationery: Adding a sophisticated touch to letterheads and envelopes.

- Packaging: Creating standout packaging designs that enhance brand identity.

What is Debossed Printing?

In contrast to embossed printing, debossed printing creates a recessed design or text on the material’s surface. This technique involves pressing the design into the material to sink below the surface level. The result is a depressed area that contrasts with the surrounding area, providing a different visual and tactile experience compared to embossing.

Benefits of Debossed Printing

- Subtle Elegance: Debossed designs are often less pronounced than embossed ones, offering a more understated look.

- Textural Contrast: The recessed design creates a unique contrast with the surrounding area, enhancing the overall texture of the printed piece.

- Professional Appearance: Debossing can add a refined and sophisticated touch to materials where a more subtle impression is preferred.

Common Uses of Debossed Printing

- Business Cards: For a sleek and professional look with subtle depth.

- Stationery: To add a refined touch without overwhelming the design.

- Packaging: Enhancing the unboxing experience with a touch of elegance.

Embossed vs. Debossed: Key Differences

When comparing embossed vs. debossed printing, several vital differences emerge:

- Visual Effect: Embossing creates a raised effect while debossing results in a recessed design.

- Texture: Embossed printing adds height and dimension, whereas debossed printing creates a dip or indentation in the material.

- Design Impact: Embossed designs are often more attention-grabbing and tactile, while debossed designs provide a more subtle and refined effect.

Choosing Between Embossing and Debossing

When deciding between embossing and debossing for your project, consider the following factors:

- Design Goals: If you want a striking, tactile design, embossed printing might be better. For a more subtle, elegant touch, debossed printing could be ideal.

- Material: The type of material you’re using can influence the effectiveness of each technique. Embossing works well on thicker, sturdier materials, while debossing can be used on various surfaces.

- Budget: Both methods can add to the cost of printing, but debossing might be slightly less expensive due to the different tooling and setup requirements.

Combining Embossing and Debossing

You might consider combining both techniques in a single project for a unique and sophisticated look. This approach can create intricate designs with varying textures and visual interest levels, making your printed materials stand out even more.

Examples of Combined Techniques

- Business Cards: Incorporating embossed and debossed elements to highlight key information and add depth.

- Packaging: Using techniques to create a multi-dimensional design that enhances the product’s presentation.

How Embossed and Debossed Printing Works?

Embossed and debossed printing are techniques used to create raised or recessed designs on various surfaces, adding a tactile dimension to printed materials. Here’s a detailed look at how each process works:

Embossed Printing

- Creating the Die: The process begins with creating a custom die, which features the design elements that will be raised. This die is typically made from metal and includes the design in a relief form.

- Preparing the Material: The chosen material, such as paper, cardstock, or other substrates, is ready for the embossing process. Ensuring the material can handle the pressure and heat involved in embossing is essential.

- Heat and Pressure Application: The prepared material is placed between the embossing die and a counter-die. Heat and pressure are applied to the material using a press. The die pushes the design into the material, causing it to rise & create a three-dimensional effect.

- Cooling and Finishing: Once the embossing is complete, the material is cooled. The raised design is firmly set and can be further processed by adding color or print elements.

Debossed Printing

- Creating the Die: Similar to embossing, debossing begins with a custom die, but in this case, the design is recessed rather than raised. The die is crafted to press the design into the material.

- Preparing the Material: The substrate is ready for debossing. It should be compatible with the pressure required to press the design into it without causing damage.

- Heat and Pressure Application: The material is placed between the debossing die and a counter-die. Heat and pressure press the design into the material’s surface, creating a depressed effect.

- Cooling and Finishing: The material is allowed to cool after the debossing process. The recessed design is set, and the material can be finished according to the desired specifications, such as adding additional print layers or protective coatings.

Both embossing and debossing add texture and depth to printed materials, enhancing their aesthetic appeal and making them stand out.

Contact For Embossed and Debossed Printing

Embossed and debossed printing are two distinct techniques that offer different visual and tactile effects. Understanding embossed and debossed mean can help you make informed decisions for your printing projects. Whether you choose embossed vs. debossed printing or combine both, these techniques can add a unique and professional touch to your materials. For expert advice and high-quality printing services, contact Perfect Image Printers. Our printing team will assist you in selecting the ideal method to enhance your project and achieve outstanding results.

Leave A Comment